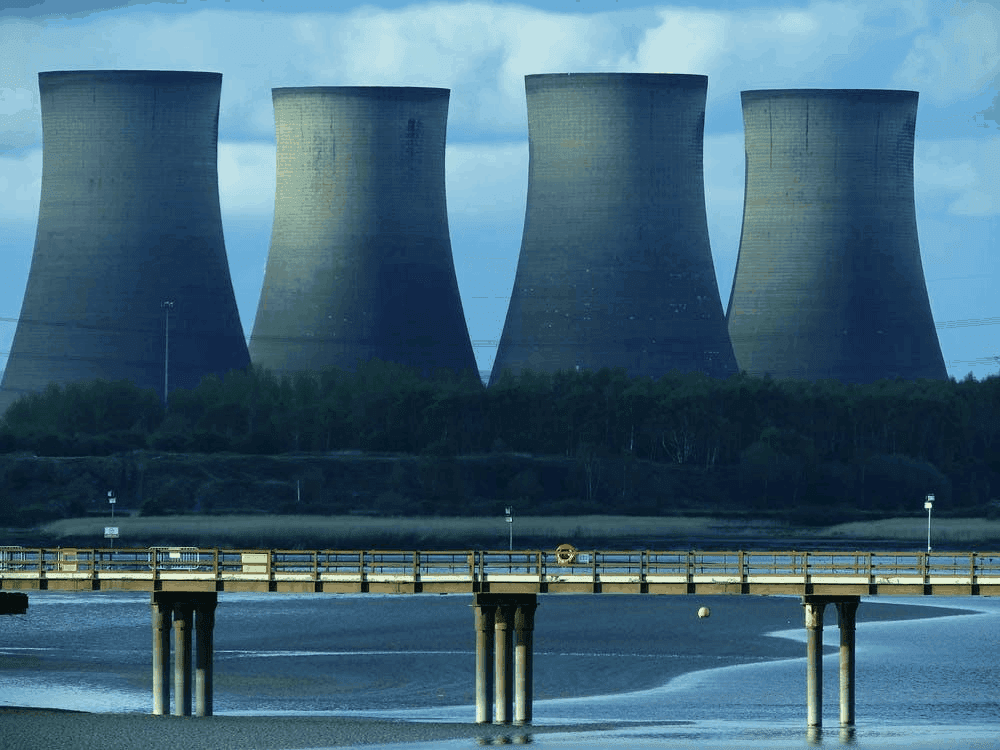

When you are looking for an energy management system, you need to have in-depth knowledge about it. Such units can be challenging to channel, especially when they are connected to each other and also to one or more cooling towers.

The energy consumptions are closely attached to their subsystems’ efficiency, such as compressors, exchangers, pumps, evaporators and more. These subsystems are also profoundly reliant on other equipment such as cooling towers; cooling tower fills, distributors of pumps and chillers, which in turn has a formal and optimum efficiency.

The chiller may have the most considerable load of any component; it may not be an immense contributor to total annual energy consumption. Therefore, it is essential to make sure that all the components work together throughout the year for refining your system’s energy performance to achieve considerable savings.

The chiller may have the most considerable load of any component; it may not be an immense contributor to total annual energy consumption. Therefore, it is essential to make sure that all the components work together throughout the year for refining your system’s energy performance to achieve considerable savings.

There are various equipment and low or no-cost operational changes that can be inspected to decrease significantly the energy use of an existing system, without risk to proper plant operation or occupant comfort. Let’s get to know some of those options to gain the highest savings:

Measure The Overall Coefficient Of Performance:

Before moving forward, the first thing you got to do is observe the consumption in chiller units and cooling towers. This will allow you to establish the COP for each unit and building by measuring the flow rate, the inlet and outlet temperature and the electricity consumption. More importantly, it can help you to construct. An overall COP includes the distributor pumps, the auxiliary pumps, and the cooling towers and factors in the climatic conditions.

Energy Monitoring systems are the most reliable and effective solutions for an energy management system that automatically records chillers’ particular power consumption in the most precise way. The system frequently analyzes, collects and reports on chiller operating data through the internet facility integrated into the system and linked to a cloud-based server. Preferably, you would be able to assemble a data history for the whole year to cover all of the seasons and as many production conditions as possible.

The critical information collected at the server can be used to manage energy and operating costs daily, which significantly helps enhance the potential performance of the chiller that saves up energy consumption.

- Invest In A New Refrigeration Technology

The latest cooling tower systems are particularly efficient, hence gaining a COP of at least 7 to 8. These refrigeration units are very modular and do not become less efficient, as they carry many small compressors that begin in a staggered sequence. However, they are very costly and not very easy to sustain.

So, if your budget doesn’t stretch that far, a similar development in energy consumption can be achieved by adding a variable power control unit.

Don’t Miss to Read: How to Choose Correct Fill for Cooling Tower Process

- Ignore Peak Load For Chiller Efficiency

Chiller efficiency is based upon a single number: peak load kW/ton. But, the typical chiller plant in a commercial building will never run at such peak conditions.

So, for office buildings, it would be best to compare the IPLV or NPLV ratings. As each building’s profile is different, these numbers are meant to be a better metric for comparison since they attempt to imitate a more typical load and operational profile for an office building in a moderate climate. Such a small difference can help you gain huge energy savings in the long run.

- Invest In Fanless Cooling Tower

The fanless cooling towers are very economically operating towers. Since there’s no much energy used to run it, there is no maintenance cost required in this cooling tower. Especially in energy efficiency point, this is the best Payback cooling tower when comparing with different models. Also, it produces very low noise.

- Take Benefit Of Cool Outdoor Temperatures

Most chillers can gain an advantage from condenser water temperature reduction during cooling weather. A chiller and cooling tower are required during the hot, humid hours of the years. So for the rest of the year, the towers can quickly and efficiently supply cooler water.

Estimating,

When the climate conditions permit, adding passive outside-air heat exchangers can decrease the need for cooling towers and the associated consumption. But, these savings may depend on the weather, load profile and equipment sizing. Thus, the analysis must be present to understand the proper control strategy.

The above points will clear out the variety of solutions for optimizing the energy management system. The most important solution might be the Energy Information System. So, the more your energy monitoring system is well-documented, the more productive these solutions will be.