The crossflow cooling tower relates to the family of mechanical flow cooling towers. The upward flow of the air chills down the hot water raining down from the hot water container at the top onto the cold water bowl at the bottom.

Cooling towers are required as they have a lot of applications in various industries. These towers are demanded to play an essential role in dealing with waste heat in a cooling system that transfers the heat to the environment. With these cooling towers, organizations can run their businesses without neglecting waste heat management.

Cooling towers can either go for a vaporization procedure wherein water gets dried up to reduce the processed heat and then cooling down the working fluid, which eventually chills the area, thus excluding waste heat. The other method is what we call a closed circuit dry cooling mode.

This technique entirely depends on air to cool down the twitching fluid to eliminate waste heat. Both methods of cooling are effective. These differences are just because of a company’s preference and its facility’s specifications and specifications. There are also two types of sections in cooling towers, and these are based on the sort of air conduction released into the tower.

Evaporative cooling towers come in a medley of sizes. They can be small enough to outfit roof-top units or large enough to meet megastructures. Usually, one can see cooling towers in biochemical plants, HVAC systems in cooling factories, oil refineries, petrochemicals, and thermal power plants.

The more prominent ones are associated with coal-fired plants, large chemical or industrial plants, and nuclear power plants. The plant needs at least two giant cooling towers to cover the entire area to reduce the heat entirely. In some cases, other cooling towers are secondary to moderate in size. They are usually placed near buildings to help release waste heat from air conditioning units all over the region.

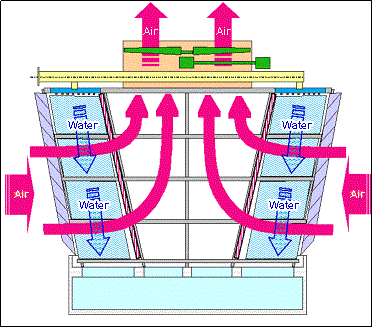

A fan is located on the roof of the device to cause airflow through the louvers and fills to be perpendicularly prevented by the hot water raindrops. The drift transmits the tower at the top.

The crossflow cooling tower can work with very much lower-than-design flow levels, as little as 30%. Since the only mechanism drawing down the water through the vents is gravity, these towers can provide even water distribution across the fill.

Towertech is a proud supplier of cooling tower products, making convenient communication between the consumers and manufacturers. To read more about the cooling machines and their purpose, check the post below –

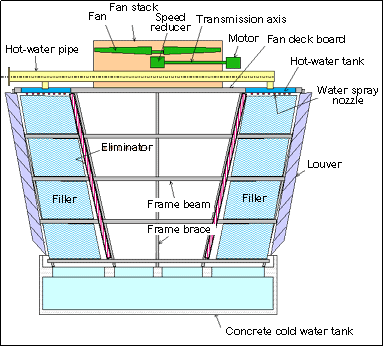

Crossflow Cooling Tower Diagram and Design

As shown in the diagram below, the water runs down the fills due to gravity in a vertical manner while the air comes in contact with it horizontally, getting the name “crossflow.” This design eliminates the need for the air to pass through the water distribution system, which is why there is no other mechanism necessary for the water to cascade down the cooling tower except for gravity.

For the water on the fill mechanisms to be evenly dispersed, a hot water basin is the standard method for designing the crossflow cooling tower.

Working Principle

The evaporative cooling tower’s working system is no different from what is generally true about cooling towers: Raising the water surface area as it flows through the capacities and water cools down via convective heat transference to the passing air.

Crossflow Cooling Tower Parts

- Hot water container: A container for the widespread collection of hot water to be evenly passed into the vents.

- Spray outlets: When water fills the surface of the hot water container, it then drains down the holes spread throughout the basin surface into the spray outlets.

- Fill: Panels onto which the water is sprinkled and cascaded to increase its surface area and be associated with the cooling air absorbed into the tower through the fill.

- Coldwater container: The container is situated at the bottom of the tower to accumulate the water-cooled down through the fill mechanisms.

- Fan: A device placed at the top of the crossflow cooling tower to persuade airflow across the capacities.

- Air inlet louvers: Air exits into the tower, keeping outside bodies such as birds from accessing the tower and preventing splattering out the cooling tower water.

- Drift Eliminator: Panels made from elements similar to that of fills to avoid water droplets entrained in the air rivulet (drift) to leave the tower and block process water loss.

- Float: A device that controls the process of water level loss due to inflation.

- Makeup water inlet: The volume of water needed for keeping proper process water levels in the container enters it.

- Water outlet: The outlet port for cooled down processed water.

- Overflow: A means of clearing extra decks of water in the bay.

- Drain: A element for managing the amount of mineral content in the basin collected during the operating cycles.

Crossflow Cooling Tower Benefits

As might have been inferred from the designs, the design of crossflow cooling towers allows for a large plenum area. This means that an entrance door could be adapted for ease of inspection. Besides, the space inside these towers makes it feasible for easy access to mechanical elements in the cooling tower.

As the water flows down the fills by only experiencing the downward force of gravity, the work would be possible for both low and high flows of hot water. This design has also made a good performance in cold climates possible.

Get in touch for more information about the cooling tower.