FRP means Fiberglass Reinforced Plastics. So what is it? It simply is a cooling tower, but the FRP is the kind of material it is made of. The FRP cooling towers are of medium size and relatively easy to install. Due to their size, you have no reason for not getting yourself one as they can be compressed into a crowded population.

The fiber-reinforced polymer is a blended material utilized to make the FRP cooling tower used in industries today. In summation, it can resist any weather situation and withstand corrosion, waterborne bacteria, and organisms. So, if you are focused on purchasing cooling towers products, you can contact Towertech.

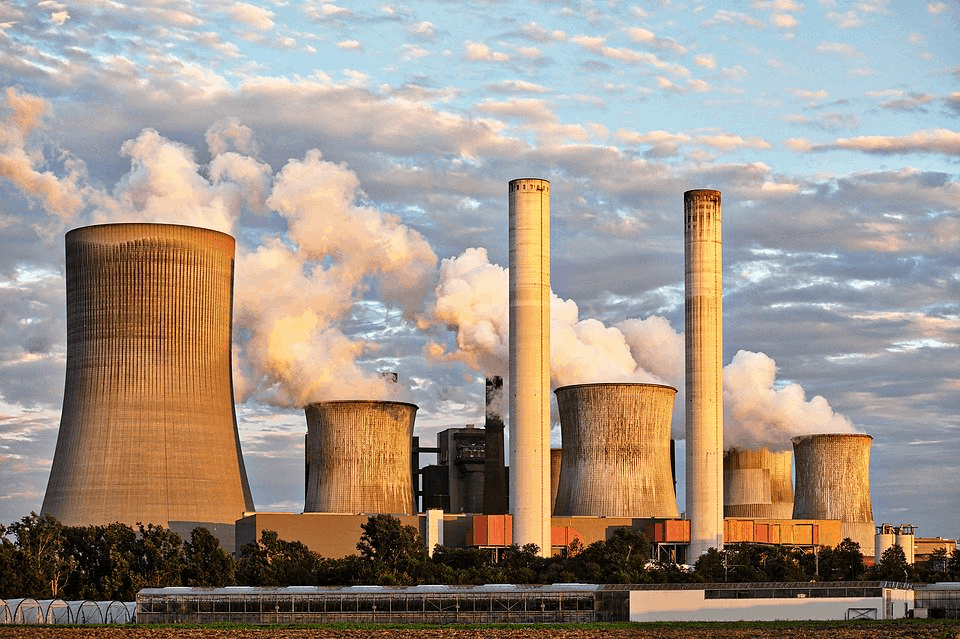

FRP Cooling Towers

It is made in such a way that it can persist against high wind swiftness the shocks and vibration can absorb up air from all the direction. It absorbs less power in general because of more limited area utilization.

In other words, the FRP cross-flow cooling tower is designed so that air must come into contact with water for heat loss to occur. The air aims to lower the warmth of the hot water. More of the importance is stated below:

Essential Facts of FRP Cooling Towers

- Pultrusion technology is usually most favored due to its constructional material used and its application for small cooling towers.

- FRP material needs less maintenance and gives low cost. However, reinforced concrete is still employed in large constructions.

- Different cooling towers include coaxed draft cooling towers, FRP cooling towers, Fanless filles, and a few others. You can pick the one which satisfies all your requirements.

Advantages of FRP Cooling Towers

Towetech manufactures a prerequisite range of FRP square cooling towers in India by following the technically advanced mechanism to improve the trait of products. Our collection can furnish many areas such as chemical plants, oil refiners, power stations, and building cooling.

Where is the FRP cooling tower placed?

They are primarily used in chemical factories, petrochemical manufactories, thermal plants, building cooling and air conditioning, large schools and hotels, hospitals and oil refineries, steel mills, power plants, and a few others.

The FRP type of cooling tower is possible either in the original drafts or induced drafts. Natural FRP induced draft cooling towers are outlined to move air up through the tower without fans so casually. Produced draft FRP cooling towers there depend on the fans to get rid of the motion.

What are the parts of an FRP cooling tower, and what is their purpose?

- The fills can be made of PVC or wood. The PVC is more likely to be employed in the FRP cooling tower to promote heat transfer by maximizing water and air contact. Fill can be sprinkled or film type depending on what serves best for the cooling tower.

- Frame and casing; the structure and casing of the FRP cooling tower are fiberglass reinforced plastics. Some towers have the edge and external casings, while the rest of the frame serves as the casing.

- Fans; the common types utilized are propeller and centrifugal fans. The FRP cooling towers with induced designs employ propeller fans, while both propeller and centrifuge are practiced in the forced draft cooling towers.

- Coldwater basin; this is where the water drips down from the fills. The bay sometimes has heaters, mainly during winter, to prevent freezing of the water in the basin.

- Air inlets; allows the air in to allow direct contact with the hot water for cooling.

- The FRP cooling tower has to possess louvers to block the entry of birds and rodents into the cooling tower. The louvers also reduce the amount of splash out, which limits water wastage and lowers chemical use. They are effective for keeping out direct sunlight to limit algae germination in the cooling tower container.

- Drift eliminators; the purpose of this in the FRP cooling towers is to remove water droplets from the air and minimize loss of process water. They affect the water droplets and air, forcing them to change direction suddenly, which separates the water and the atmosphere. The water flows back into the cooling tower.

- Driveshafts; function by transmitting power from the motors output shaft to the gear reducer’s input shaft. The driveshaft needs to be corrosion-resistant.

- Gear reduced solutions; gearboxes available for the FRP cooling tower are designed to accommodate horsepower and fan speed.

The FRP cooling towers are available in natural draft cooling towers and induced draft cooling towers. It has two different air mechanisms, out of which you can pick out the one that suits you the best.

Different frames allow you a variety of space and magnitude. From which, you can pick one of the square-shaped cooling towers for a more enhanced immensity of space.

Besides, you can pick from different color options available along with the forms. The benefits of FRP cooling towers are many, and the advantages mentioned above will provide you with some understanding of it and how it works. So, when searching for an FRP cooling tower manufacturer, visit us at TowerTech India, and we will furnish you with whatever part you are looking for.