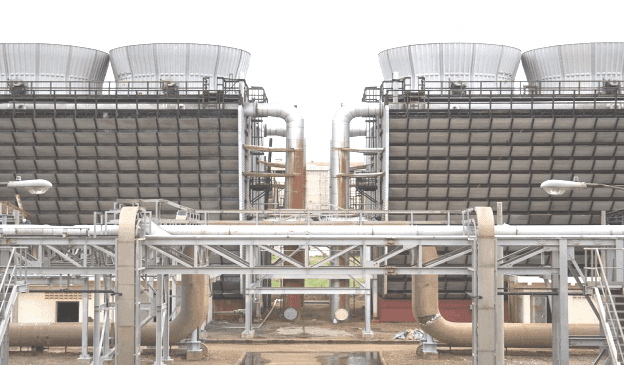

Cooling towers usually play a really crucial role in various industrial processes. They basically help to remove excess heat and are typically used in power plants, manufacturing facilities, and HVAC systems. However, they can also create some generic problems if these are not maintained properly. One significant issue in this case is called “drift.” Drift can usually cause environmental and operational challenges. This is where cooling tower drift eliminators come into play.

What is Drift?

Drift basically refers to small water droplets carried by the air that goes out of the cooling tower. These droplets usually contain significant amounts of chemicals and minerals. As a result, they typically become a source of environmental contamination. Additionally, they can also cause equipment corrosion. This loss of valuable water from the system can generally lead to increased water consumption. This can further lead to higher operating costs. Hence, you need to understand how you can tackle this problem for an efficient cooling tower operation.

The Role Of Water Eliminators

Drift eliminators in cooling towers are components that are usually designed and installed within cooling towers. Their primary function is to reduce the distribution of water droplets into the surrounding atmosphere. These devices use a combination of barriers and baffles. Thus, this process eventually prevents the water from escaping into the surroundings.

Main Uses of Water Eliminators

1. Environmental Protection

Water eliminators can also help to reduce the environmental damage to some amount. This environmental protection can be done by preventing the spread of chemicals and minerals into the atmosphere by these eliminators.

2. Protects Expensive Component Parts

Next up, drift eliminators are really important for protecting the lifespan of your cooling tower components. This is because they generally reduce the risk of corrosion and deterioration in your water cooling towers. This is done as key components are typically protected from the harmful effects of this drift. As a result, this preservation helps in increasing the lifespan of the cooling towers and also reduces maintenance costs.

3. Water Savings

Water conservation can be yet another concern for you. Water eliminators can help by collecting this drift. And then push it back into the tower basin. This process generally maintains the overall water balance within the cooling system. As a result, the need for extra water is reduced.

4. Energy Efficiency

Drift eliminators can help you indirectly support energy efficiency. This is due to the fact that they will ensure that your cooling towers operate at optimal performance levels. This optimization will then generally reduce the load on downstream equipment. Hence, energy consumption is reduced.

Main Advantages of Using Water Eliminators

1. Reduced Environmental Damage

Water eliminators help to reduce the release of contaminants into the atmosphere. This typically helps in meeting environmental regulations. Thus, this usually contributes to a cleaner environment.

2. Increases The Lifespan

Water eliminators can also help you increase the lifespan of water cooling towers. This is usually done by protecting sensitive components from corrosion and deterioration. This then results in lower maintenance and replacement costs.

3. Water Savings

Collecting and pushing the drift back into the system can help in conserving water. This is basically important in regions that are facing water scarcity.

4. Energy Savings

Proper water cooling tower operation will also help you to reduce energy consumption. Water eliminators typically help in this efficiency by maintaining proper water distribution.

5. Cost Savings

Reduced water and energy consumption by these eliminators can basically lead to lower operating costs. Additionally, the extended lifespan of these water eliminators will result in lower maintenance expenses.

How to Choose the Right Water Eliminator

Firstly, you need to choose the kind of material required to build it. This is because it can generally affect the durability and performance of it. Therefore, you should go for materials that are usually resistant to corrosion and chemicals.

Secondly, high-quality eliminators will usually collect more water droplets than any other machines. Thus, this can result in better performance of your cooling towers.

Also, some water eliminators usually require more maintenance. So, you should go for an eliminator that gives off good performance with less maintenance needs.

Lastly, purchasing costs are also an important consideration. However, long-term benefits such as water and energy savings should not be compromised because of cost factors.

Conclusion

Water eliminators are really crucial components of cooling towers. This is due to the fact that they play a really important role in improving the performance and extending the life of your cooling towers. Moreover, getting high-quality water eliminators can also help you support environmental sustainability.

You can now increase the cooling tower capacity with the advanced water eliminators made by Tower Tech. Contact us today for top-quality services and sustainable solutions.