Energy efficiency is not only a cost-saving technique, but it has also become an essential one among today’s rapidly evolving industrial ecosystem. As industries scale up to control the business processes become more and more complex, despite this, organisations continue to put significant efforts and resources into finding more effective cooling systems.

A cooling tower is one of the most important components in this system, as the proper optimisation of cooling towers leads to a significant reduction in energy consumption in the cooling system and helps in green industrial development.

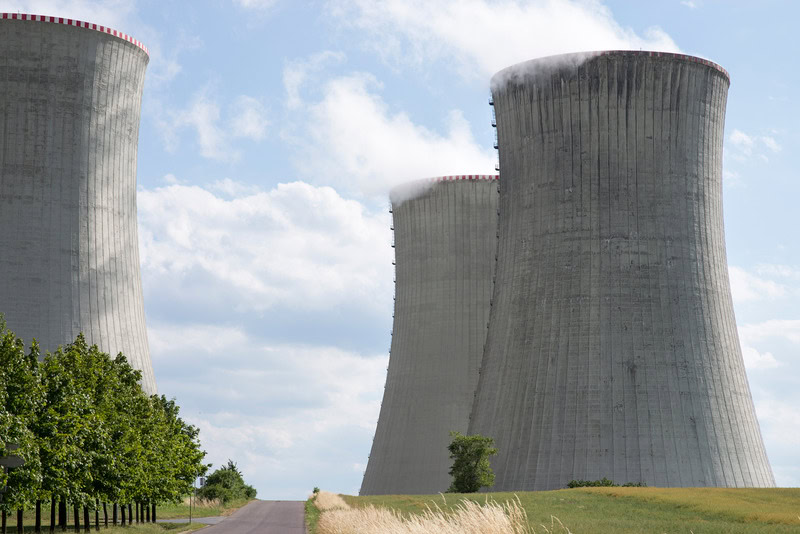

What Are Cooling Towers?

Cooling towers are systems designed to reject heat generated during any industrial process. When water is circulated through a heat exchanger, the water absorbs excess heat, which is then cooled by exposure to air. The cool air is then recirculated back into the system. This operation is used throughout manufacturing plants, refineries, power stations, data centres, and many other types of plants where effective heat management is mandatory for performance and safety.

Why Cooling Towers Matter in Energy Efficiency?

A cooling tower plays a crucial role in energy efficiency, as cooling towers are used to maintain thermal stability by reducing the workload on mechanical equipment such as chillers and compressors. These systems not only protect equipment but additionally keep up process temperatures at optimal levels so energy is effectively utilised throughout all activities.

Reducing Energy Consumption in Cooling Systems

A properly designed and managed cooling tower is a far more efficient means of lowering the overall energy usage by itself. When water is artificially cooled, reusing it in a system requires a lot less energy than compared to cooling it with refrigeration. Especially this is useful in large industries where even small improvements in energy translate to a source of substantial savings.

In addition, the cooling towers enable industries to switch from the energy-intensive air-based cooling to water-based cooling, which is often more efficient in heat removal. A simple change can play a great part in reducing energy consumption in cooling systems, especially when integrated with smart technologies.

Optimising Cooling Tower Performance

The key to energy efficiency lies not just in having a cooling tower but in optimising cooling tower performance. This includes several operational practices and system upgrades, such as:

- System maintenance should be performed regularly to prevent scale accumulation as well as corrosion, which can stop heat transmission from happening.

- The system utilises Variable Frequency Drives (VFD) for managing fan speeds according to present cooling requirements.

- The system needs water flow controls for efficient evaporation processes and even distribution of resources.

System longevity increases while energy consumption decreases when these strategies are put into practice.

Energy-Saving Cooling Technologies

With modern cooling towers, energy saving in the cooling goes beyond the conventional system. These include:

- Hybrid cooling towers: They use dry and wet cooling, depending on climate and load, to consume little water and energy.

- Smart Sensors Integration with loT: Providing real-time performance tracking and predictive maintenance to reduce energy waste.

- High Efficiency Components: Achieving high cooling capacity while saving energy is possible via high-efficiency components.

These innovations & regular maintainance of cooling towers reduce utility bills without compromising the sustainability of the facility.

Cooling Towers and Industrial Sustainability

Other corporate sustainability goals align and push the business toward industrial cooling solutions that are both efficient and eco-friendly. Energy-efficient cooling towers must work on:

- Lowering your overall carbon footprint by using less electricity.

- Efficient circulation and water treatment systems minimise the use of water.

- Extend equipment life and minimize recurring need for frequent replacements as well as its associated production, transport and environmental impact.

Today, energy-efficient cooling practices have become an important part of long-term planning for competitiveness in an industry and following the environmental regulations.

Choosing the Right Cooling Tower for Maximum Efficiency

Cooling towers come in various designs and types, each suited to specific applications and operational requirements. The choice of a cooling tower depends on several critical factors. Such as:

- Heat load and operating conditions

- Local climate (wet vs dry regions)

- Space availability for tower placement

- Water resource accessibility and quality

Industrial cooling solutions select and configure cooling towers in a manner of how well they achieve their energy goals without sacrificing operational performance.

Conclusion

Cooling towers play an integral part in reducing cooling system energy consumption and developing energy-saving cooling technologies, making them an essential path to sustainable, high-performance industrial operations. In the industry, where there are efforts to work with greater efficiency, cooling towers hold an important role in doing so.

In making the right investment in systems and practices, businesses not only ‘save’ operational costs but also undertake a large part of achieving environmental and energy goals. In the long run, upgrading old systems, designing a new facility, and prioritising energy efficiency in cooling towers will certainly pay off.