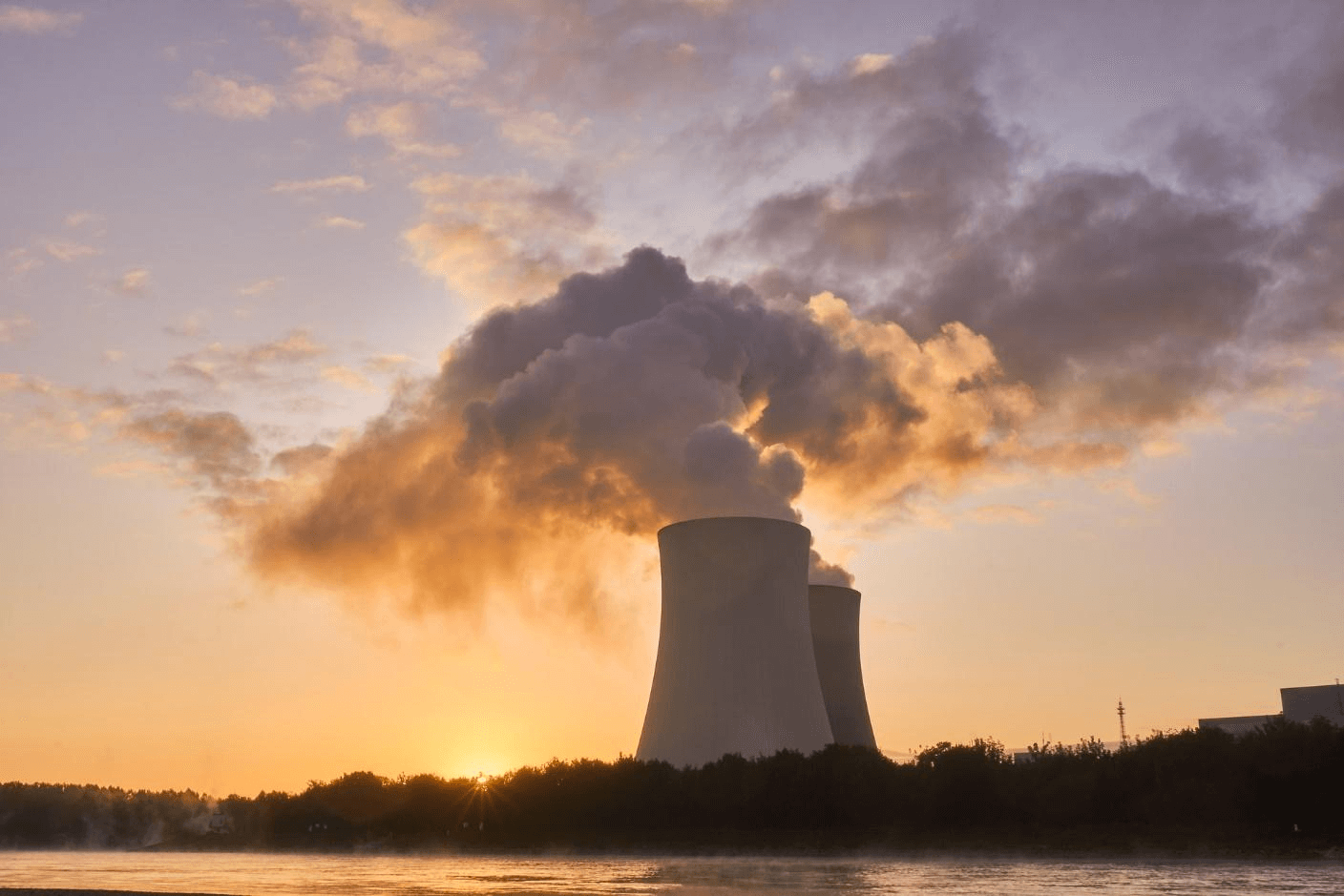

How much would you want to increase the efficiency of your cooling tower? Factory energy and fuel expenses cost businesses billions of dollars each year. There has never been a better moment to buy energy-efficient items since they are now more affordable than ever. However, since HVAC systems are the most significant energy users in a building, improvements should be prioritized. Industrial Cooling towers serve an essential role in decreasing algae and suspended particles and may host one of three subgroups.

Cooling towers use evaporation and heat transfer to chill water. If you need to cool anything by 10 degrees, you’ll lose 1% of your water supply due to evaporation. Scales left behind by evaporation may limit cooling tower effectiveness and need expensive maintenance or acid cleaning.

The chemistry of a building must be carefully maintained to preserve its durability and efficiency, and cooling towers are an essential component of that process due to the machinery present in industrial buildings that require both open evaporative and closed cooling water systems. Because the summer heat makes it more challenging to cool air, these towers must be kept in excellent shape before the warmer months come.

4 Ways to Maintain Industrial Cool Towers

As a result, they ultimately “wear,” putting a strain on the system’s resources (the machinery and the water supply). Heat exchangers, industrial equipment, and heating, ventilation, and air conditioning (HVAC) systems, for example, would lose their ability to absorb heat from their surroundings. Even minor dips in cooling power may cause significant delays and even product loss in organizations that depend on cooling towers for critical processing equipment, HVAC, refrigerators, and freezers.

The temperature of the water released from an underused cooling tower will rise with time. Energy costs are predicted to grow by up to 6% for every two degrees Fahrenheit an item works at. On the other hand, cooling towers may be optimized by performing a few simple maintenance operations, possibly lowering a building’s energy expenses by up to 15%. Preventive maintenance is advantageous since it extends the life of your cooling system, decreases operating costs, and protects your original investment. Here are 4 ways to improve the performance of your Cooling Tower as suggested by Industrial Cooling Tower Manufacturers.

Regular Inspection

Regular inspections should form the basis of any cooling tower preventive maintenance plan designed for an industrial setting. It is essential to do routine checks on the gearbox and the water pump to ensure that nothing has become dislodged.

During regular inspections, issues such as corrosion, scaling, and others of a similar kind may be discovered.

If you can identify these issues early, you will be able to address them and keep your chiller in tip-top condition.

Removing Deposits of Impurities

The water that travels through the circulation system of the cooling tower is at risk of being tainted with contaminants, some of which may be accumulated by the system. They make it more difficult for the chiller to maintain an even temperature across the space. More energy is going to be needed to raise the temperature of the unclean water up to the level that is wanted.

If your cooling tower does not have a cleaning system, you will need to clean the tubes regularly and monitor the chiller for symptoms of sedimentation.

Your chiller’s useful life might be cut shorter if pollutants condense on its inside and cause condensation. Consequently, such deposits need to be removed regularly to keep the tower free of issues.

Improving Airflow

The chiller won’t work until the fans are spinning. The chiller’s airflow might be impeded if any of the components come loose or the fan blades have been damaged.

The tower’s ability to disperse air effectively is diminished if debris builds up and sludge forms.

Algae growth in the airways may lead to obstructions and decreased efficiency.

Using SBR for Water Treatment

The water that is held inside the cooling tower immediately impacts how it performs its purpose. On the other hand, dust, minerals, and other contaminants in your chiller may lead to various problems.

You may be able to purify your water and get rid of impurities with the aid of scale and bio-removal systems, which won’t impact how efficiently your chiller works. Scale removal and bio-removal technologies are also offered as options.

Your chiller will be able to operate to its maximum capacity since it maintains the water’s original quality while also preventing the growth of potentially harmful bacteria and germs in the water.

Conclusion

You can ensure that your industrial cooling tower stays in the best possible functioning condition by sticking to the four aspects above, which will also ensure that it lasts as long as possible and consumes the least amount of energy possible.