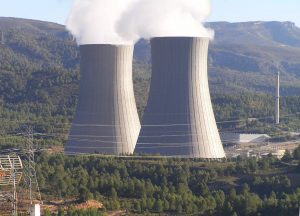

If you believe that cooling towers which are cylindrical and broad at the base are established only in nuclear plants, then it is not entirely true. Along with nuclear plants, it is used in many industries. Just like the name indicates, cooling tower work to keep the system cool. Overheating can put the entire functions of an industrial unit at a halt. To prevent such incidents, many industries are depending on cooling towers. Overheating often damages the parts of the machinery and It also causes wastage of money and time. So if you are establishing a new industrial unit, you should find a reliable cooling tower manufacturer to solve your concerns. Here is everything that you should know about cooling towers.

How does it work?

Just like the name indicates, it works for cooling down the water which circulates in the system. There is a series of large fans that flow air into the cooling tower. This air connects directly to the heated water which comes from the condenser. During the process, the amount of water evaporates which leads to the cooling action. After that, the cooling tower shoots the cooled water to the condenser.

Different types of cooling towers:

There are various types of cooling towers. Each type of cooling tower is manufactured differently and varied ineffectiveness.

Natural Draft Cooling Towers:

To cool down the water, the natural draft cooling tower uses natural convection and circulates the inside air. This type of cooling towers are manufactured considering the simple ideology; moist air rises above the cool or dry air, and so it creates a continues to flow.

Mechanical Draft Cooling Towers:

The different mechanism is used in mechanical draft cooling towers for the air circulation inside the tower. Which is entirely different from the natural draft cooling towers. These types of cooling towers are manufactured considering advanced techniques. These towers can also be placed indoor. One of the critical features of mechanical draft cooling towers is that the airflow in the tower can be regulated. The only reason that many industries have not installed this type of cooling tower is due to its high cost.

Here are some of the typical applications of cooling towers:

Cooling towers are installed in hotels, hospitals, commercial buildings, residential areas, etc.

It is crucial for the electrical generation plants

Oxygen plants

Biogas plant and renewable power plants

Milk and dairy

Refrigeration plants

Injection molding machines

Induction heating steel furnace

Hydraulic oil coolers

Here is the list of some of the industries that are highly depended on cooling towers for error-free functionality:

Oil refineries and manufacturing units

Metal casting plants and steel plants

Solar power plant

Vehicle manufacturing industry

Food processing industry

Chemical sector

Dairy products processing units

How are cooling towers designed?

Two types of cooling equipment are used, open circuit and closed circuit. Both the systems bring the same output and so it is important for you to understand how they work and what sets them apart from each other.

Open Circuit Cooling Towers

Warm water is distributed into a fill. At this time, a fill gives an increased surface area for the air and water to connect. This leads to maximum evaporation, followed by the collected cold water in a basin released to the condenser — the process repeats. The heated air is discharged and cannot enter into the cooling tower.

Closed Circuit Cooling Towers

This design prevents any direct contact between air and the water or glycol mixture used. Two fluid are used, one is to flow the warm water and the second one is a tube bundle. When water goes through the tube bundle, it cools down using air that is blown by the fans.

The size of the cooling towers depends on the requirement. The materials used in its making is also different. The conventional materials used in the manufacturing process is stainless steel, plastic, and woods. However, most of the customers prefer to go with galvanized stainless steel as it comes with durability and longevity.

How to find reliable cooling tower exporter or manufacturer?

Quality installation:

There are lots of manufacturers in the market, but approaching the one with good industry experience and reputation would be a wise decision. Before making the decision, you should at least check the website of the company and also go through the reviews given by previous customers. If you find positive reviews, you should ask for the quotations.

Cost-effective solution:

You should ask for the quotations to a number of companies. There is no need to go along with the one that offers the cheapest deal, but you should look for the combination of quality service and reasonable price.

Maintenance:

The cooling tower requires proper maintenance. Whether you have installed a cooling tower from an FRP cooling tower manufacturer or you have approached the manufacturer of a field-erected cooling tower, you should check whether the company seems promising on quality maintenance service or not. If the cooling towers are not maintained properly, then the errors in the systems are inevitable.

Summary:

Cooling towers work to prevent overheating of the system. Any industry needs the proper installation of a cooling tower to keep the system in the flow. Any cooling tower can be installed. If you opt for the Mechanical Draft Cooling tower, then it might cost you more than the natural draft cooling tower. Finding a reliable manufacturer is also easy. You only need to look for a perfect combination of cost, quality and proper after-sale service.