The primary purpose of any cooling tower is to remove heat from the water and subsequently, the crossflow cooling tower has the same idea. Crossflow tower belongs to the family of mechanical drift cooling towers.

This cooling tower is mainly used in the heating, ventilation, and air conditioning (HVAC) system. Additionally, it is also used in large-scale cooling and air conditioning systems. It works by crossing air vertically against water horizontally, and hence, it’s named ‘crossflow.’

The Concept

The working principle of a crossflow cooling tower is to allow the water to flow vertically through the fill media. In contrast, the air horizontally flows across the water via the louvers. The hot water flows in by gravity, whereas cold air crosses the hot water, resulting in cold water.

Space Requirement

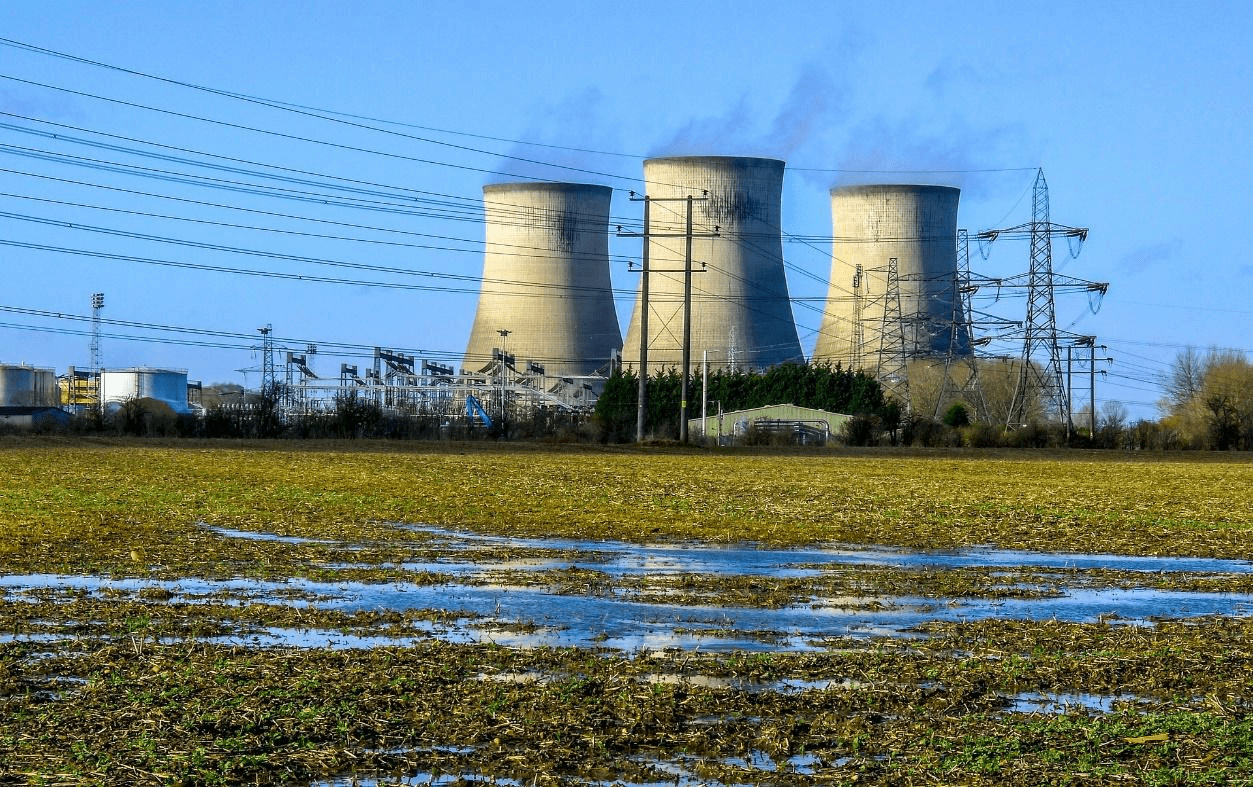

Industrial cooling towers manufacturers require more plan area. Thus, the area with a lower population and spaciousness is suitable for constructing this cooling tower. Moreover, the site needs to be less polluted.

Maintenance

Proper maintenance of this tower can save you time, money, energy, and life of the tower. You need to keep the crossflow metal cooling tower well-maintained, enabling the entire cooling system to perform at optimum efficiency by conserving both energy and water. Most of the cooling tower consists of a larger plenum area. This makes the inspection, repair, and maintenance much more manageable.

Water Distribution

Water distribution in this cooling tower is pumped to the top and discharged into a hot water basin with nozzles. This entire process depends upon the gravitational force.

Variable Flow and Cold Weather Operation

Variable flow and Cold weather operation can be easily affected by water distribution. This tower can utilize a minimum of 30% of the design flow and maintain even water distribution across the fill media.

Nozzle cups are built on the inboard side in the winter or cold weather to keep the heat away from the fill medium’s side exposed to cold or snow.

Crossflow Cooling Tower Parts

- Fill: Water flows down due to gravity and is primarily hexagonal. The cooled air pulled into the tower through the fill interacts with the panels and water is sprayed and showered on that to increase its surface area.

- Fan: Fan is placed on the top of the crossflow cooling tower to induce airflow across the fills. It supplies cool air into the cooling tower. In this way, it helps a lot in the agitation process of a cooling tower.

- Hot water basin: It is a container used for the widespread accumulation of hot water. The hot water basin evenly passes hot water into the nozzle.

- Spray nozzles: When the water fills the surface of the hot basin, it drains down the holes and spread throughout the basin’s surface into the spray nozzles. These nozzles enable the water to spread out over a large area.

- Coldwater basin: A particular container is placed at the bottom of the tower to accumulate the water-cooled down through the fill. This container is known as a cold water basin.

- Makeup water inlet: If there’s a shortage of water required for maintaining proper process water levels in the basin, makeup water enters it.

- Air inlet louvers: The air inlet louvers prevent external bodies, such as birds, from entering the cooling tower and splashing water.

- Drift: The component of a cooling tower that indicates water loss is called drift.

- Drift Eliminator: Air enters through the louvers and fills to drift eliminator.

- Float: This component regulates the water coming into the tower to replace the lost water as drift. Float opens and closes depending on the level of water in the basin.

- Drain: Drain is considered to be an essential element of the tower. It is used to regulate the number of salts and sediments accumulated at the bottom of the tower over time.

- Overflow: It helps to get rid of excess water in the cooling tower basin.

- Water outlet: The water outlet is the exit port for cooled-down process water.

Tower Material

The material used in making crossflow cooling towers includes:

- Stainless steel

- Glass fiber

- Galvanized steel

- Concrete

Plastic is often used for fill, including PVC and polypropylene. Nozzles are mostly made up of ABS, PVC, and glass-filled nylon. Fans are made of aluminum, molded glass fiber, or galvanized steel reinforced with plastic.

Factors Affecting Crossflow Cooling Towers

Following are the factors that affect crossflow cooling towers:

- Heat load on the cooling tower is proportional to its size and cost. The degree of cooling tower relies on the operating temperature of the process. In winters, a cooling tower requires a higher amount of heat load as compared to in summers.

- It does not matter how much heat loss or circulation flow is for the cooling tower’s greater performance. What matters is flow rate, as it affects the performance of the cooling tower.

- The cooling tower is affected by cold weather because water is sent down to the fillers, and there is a high risk of solid formation. These solids affect the running of water.

Hence, these were the factors that affect cooling towers. If any part is damaged, then look for the cooling tower services as soon as possible. A crossflow cooling tower is considered much better than other types of cooling towers.