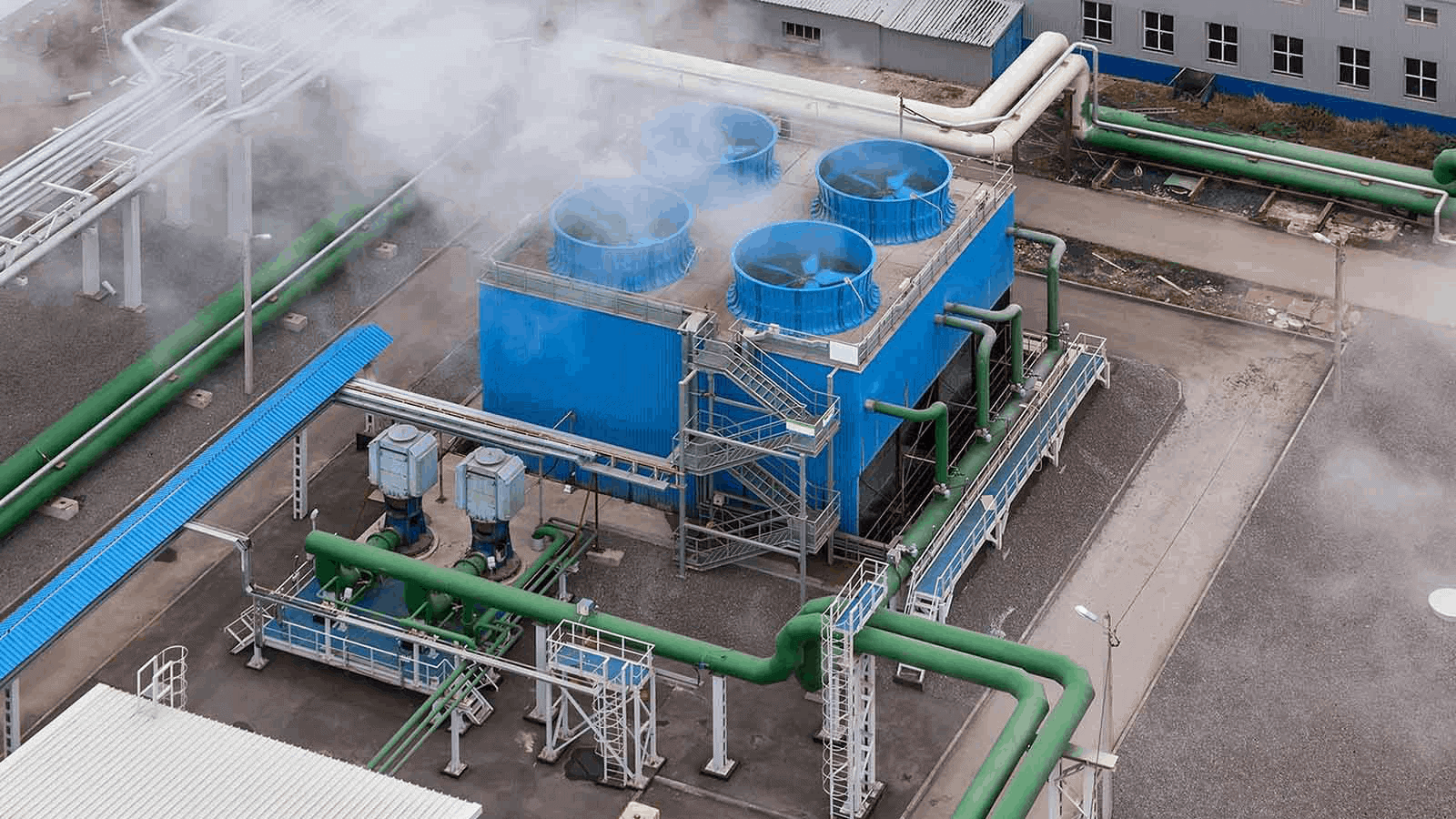

Cooling towers are important components of many industrial processes. This is because they help in the efficient operation of equipment and control temperature. Frequent cooling tower inspections are necessary to guarantee longevity and peak performance. We’ll go over the main advantages of carrying out these inspections in this blog article and will try to explain why they are essential for companies in a variety of sectors.

1 Inspections Prevent Expensive Repairs

One of the main advantages of regular inspections is to prevent expensive malfunctions. Inspections by cooling tower services help in preventing minor issues. Thus helps them from turning into serious malfunctions by seeing and resolving such problems early on. By preventing costly repairs, this proactive strategy will help you save money. It will also reduce downtime and guarantee the continuous operation of equipment.

2 Improving the Efficiency of the Equipment

In any industrial environment, efficiency is critical. Frequent inspections make it possible to spot inefficiencies. The most prevalent problem with cooling tower systems is corrosion. This is caused by a chemical reaction between air and other chemicals in the water. This basically damages metal tower components. Metal breaks down as a result of this reaction.

In the beginning, this could lead to inefficiency and increased energy use. But if things continue to get worse, then there’s a good chance that severe equipment damage and expensive repairs could happen. If corrosion is detected during a routine inspection, action can be taken to address minor corrosion problems. Thus preventing any costly repairs in the near future.

3 Prevention Of Scaling

Another cooling tower problem is Scaling. The accumulation of minerals or chemicals on tower surfaces that were broken down during tower operation is referred to as scaling. If scaling is not detected and fixed right once then it could potentially harm internal tower surfaces. Even in less severe situations, it lowers the tower’s efficiency. This could eventually raise operating expenses.

Frequent inspections are an excellent method of spotting scaling. Skilled professionals can help to determine the underlying causes of scaling problems. Thus they can suggest strategies to fix this problem. They can also help detect any excess build-up during normal operations.

Industrial companies may maximize the efficiency of their cooling systems by taking quick action to resolve these problems. One can also eventually cut down on energy use and operating expenses by investing in cooling tower maintenance.

4 Ensuring Regulatory Requirements

Companies can avoid fines and penalties by ensuring that cooling systems meet regulatory requirements. Furthermore, regular inspections can ensure that your companies adhere to local, state, and federal requirements.

Most of these laws and policies are made by the government. This is done to prevent Legionella bacteria from growing and spreading. Respecting these guidelines can also help to maintain a sustainable ecosystem.

5 Protecting the Health And Safety of Employees

Employee health and safety are typically the top concerns for companies in the industry. Inspections of cooling towers are crucial for identifying potential health hazards. Risks such as Legionella contamination or microbiological development can be among them. Companies that address cooling tower problems right away can lower the hazards to the health of their workers. As a result, tower maintenance companies may support the maintenance of a safer workplace.

6 Enhancing the Quality of Water

Maintaining water quality is necessary to prevent corrosion and the growth of microorganisms. Businesses should record metrics about water quality for this purpose. This can involve measuring the pH, population of microbes, and water conductivity. Businesses can ensure that their cooling systems operate as efficiently as possible while lowering the chance of corrosion by taking this action.

7 Increasing Reliability of Systems

Reliability is essential. Especially for companies that depend on cooling towers to maintain their operations. Frequent inspections can help in the early detection of any flaws. Thus enabling improvements and fixes. Therefore, companies can reduce the chance of unplanned malfunctions and downtime by improving system reliability. This can eventually increase output and satisfy customers and staff.

Conclusion

Businesses in various industries can benefit greatly from routine cooling tower inspections. These inspections help to improve machine efficiency and help to avoid expensive repairs. Companies can maximize efficiency through the implementation of preventive maintenance and routine inspections. By this, companies can also increase the overall quality of their cooling tower operations. Hence, this may result in increased profitability and operational efficiency.

Discover the Tower Tech difference right now! We can handle maintenance, repairs, or the installation of a new cooling tower. You can rely on our industry-leading standards and high-quality goods to maintain the efficiency of your operations. Get in touch with us right now to find out how Tower Tech can reasonably and dependably handle your cooling tower demands.