Outside/Inside Approach to Evaluating Concrete Elements in Natural & Mechanical Draft Cooling Towers

When a Cooling Tower is in use, its reinforced concrete structural materials are often in a state of uncertainty until the tower is dismantled, cleaned, and checked thoroughly by specialists with the necessary evaluation competence. After a short-duration outage, cooling tower assets are usually the last piece of equipment to be taken down, and then they are the first to be raised during re-commissioning. This is true whether the function of the cooling tower is a natural or mechanical draught.

When it comes to generating fiscal budgets for assets that are only partly known about their state and whether or not they are “fit for service,” the task of maintenance staff is one of the most challenging jobs in the whole organization. Because certain external surface portions of the reinforced concrete foundation and superstructure are reachable from “outside” when the cooling tower is operational, it is essential to note that these locations are not open to the public.

Advanced Cooling Solutions for Water Conservation

As freshwater becomes harder to find and laws about how to use it get stricter, saving water is becoming an even more critical part of the cooling industry. This is likely to keep happening. Manufacturers of cooling equipment are coming up with new hybrid cooling technologies to meet the market demand for water conservation.

This study looks at the many different kinds of cooling technologies that are on the market right now. These include wet cooling, dry cooling, and some hybrid cooling technologies that are newer and fall somewhere in the middle. It also talks about how water and energy work together in the cooling process.

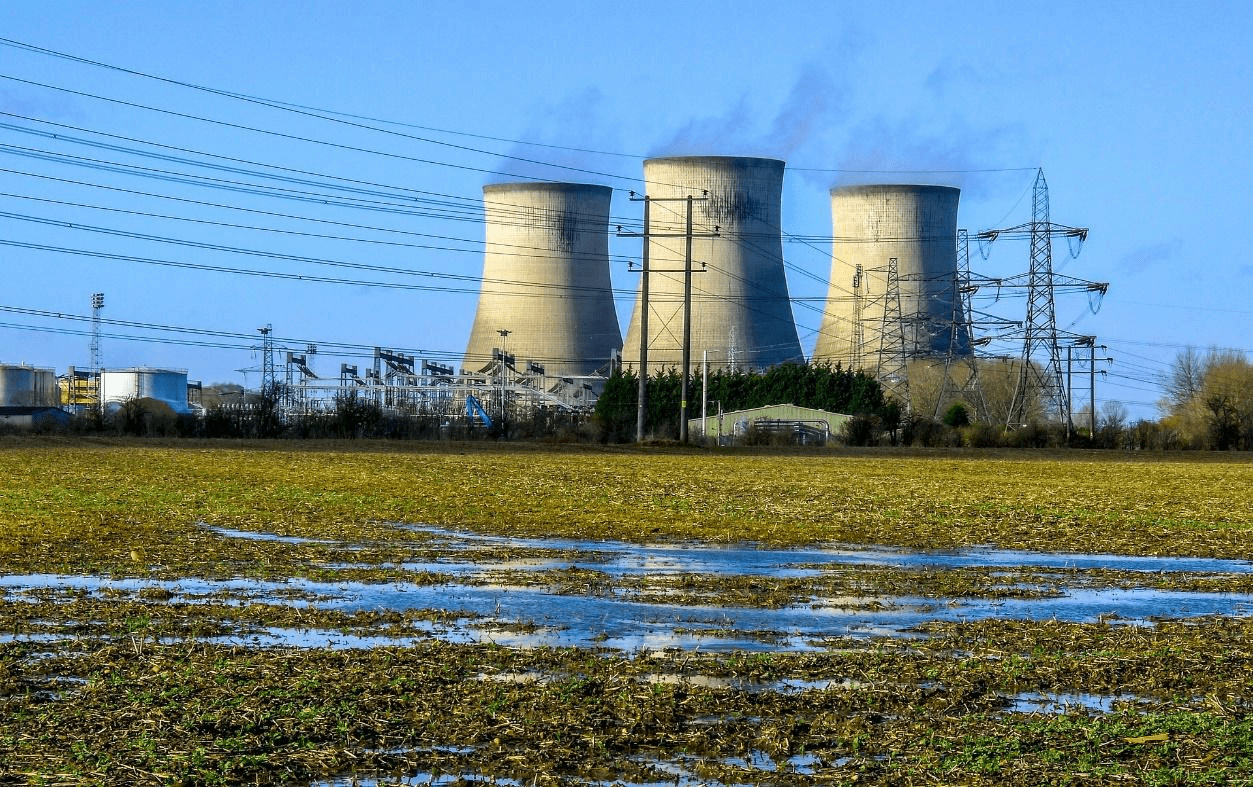

More than 80% of the electricity used in the U.S. comes from thermoelectric plants that use water to cool down. These plants take 143 billion gallons of fresh water from the environment (541 million cubic meters). In thermoelectric power plants, the two most common cooling methods are once-through cooling and evaporative cooling. The vast majority of power plants that use once-through cooling are either older plants in the east of the United States or plants near the coast that use saltwater as their cooling medium. Evaporative cooling is often used in newer buildings and places with drier climates.

Sustainability In Cooling System Operation

Several different ways can be found to use the idea of sustainability in cooling systems. Concerns include the system’s reliability, how it affects the environment, and the balance of the ecological system. This means that many different things, fields of study, and ways of doing things need to be considered, not just for the cooling system in question but also for other services and ecological systems.

There are papers that look at and talk about different factors and topics that affect the sustainability of a cooling system, including how it works, how long it lasts, and how it affects the environment. The ultimategoal is to improve sustainability. These things and topics include how they affect the environment, how they work and how long they last, and how the cooling system works.

Electrical energy is one type of energy that cooling systems use, and the water used as make-up water comes from a natural resource. Even though some places or businesses have their power plants, the vast majority of cooling systems get their power from power plants in other places, whether they are privately or publicly owned. The relevant generation plant will affect natural resources in terms of the fuel they use and the source of water they use in their operating plant.