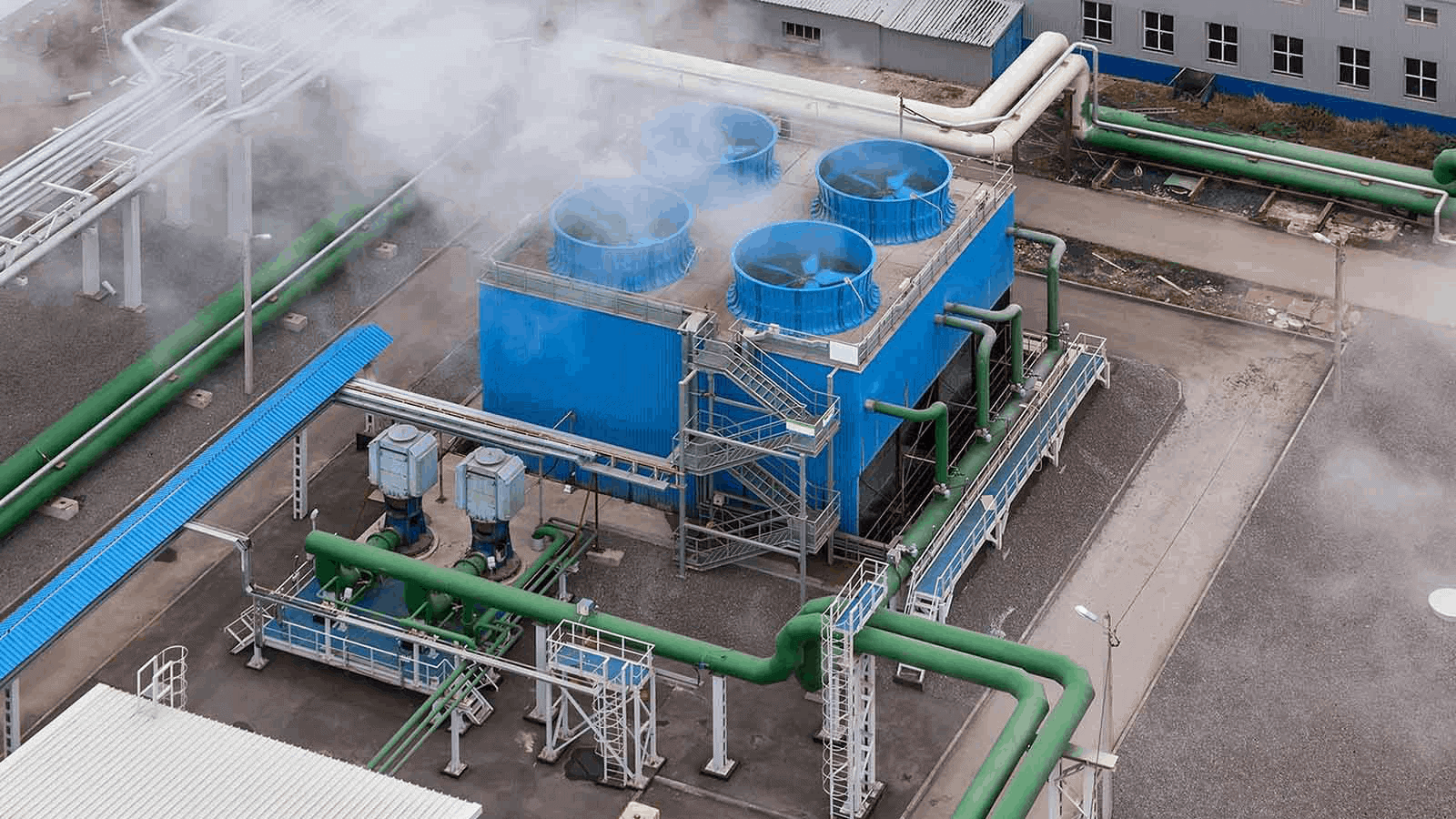

Timely cooling tower water treatment is essential to maintain the system’s performance and long equipment life. Cooling tower water treatment addresses the organic growth, fouling, corrosion, and scaling in the cooling tower, which is essential to prevent low plant productivity, downtime, replacement of costly equipment. Let’s know the basics of the cooling tower water treatment system and how does it work.

Cooling tower water treatment system:

Cooling tower water treatment system is an arrangement of technologies that aims to remove harmful impurities from cooling tower circulation water and feed water. Different types of water treatment systems apply as per the specifications of the particular cooling tower. The configuration of the water treatment system depends on the following factors:

- Type of the cooling tower

- Quality of the feed water

- Manufacturer’s recommended quality requirements of the system’s equipment

- Chemistry of the circulating water

- Regulatory requirements of wastewater

- Type of heat exchanger

- Cycle of concentration

A basic cooling tower water treatment system includes some type of chemical feed, filtration, clarification, and automated monitoring. The exact combination of treatments determined based on the impurities present in the water and so it is important to consult an experienced cooling tower water treatment service provider to get the most suited cooling water treatment. If your tower has a complex requirement then you need to go with a proper customized water treatment plan.

Cooling tower water treatment system often combines the technologies that are essential to regulate the level of alkalinity, chlorides, iron, hardness, silica, TDS, TSS, sulfates, and organic matter.

How does a cooling tower water treatment system works:

A typical cooling tower water treatment system works with the following steps:

- Cooling tower makeup water intake

- Filtration

- Ion exchange

- Chemical addition

- Side-stream filtration

- Blowdown treatment

Cooling tower makeup water intake:

The cooling tower makeup water is first drawn from its source, which could be raw water, city water, treated-water, recycled water, well water, or water from any other surface water source.

Whether your cooling tower requires water treatment and if yes, how frequently it is required is decided from the quality of the makeup intake water. The water treatment at this stage includes removing hardness and silica and stabilize and adjust the pH level. The treatment addresses two issues at this stage of the process, one is the optimization of tower evaporation cycles and minimizing the water bleed rate to drain.

Filtration:

With filtration, certain types of organic matter, sediment, and turbidity can be removed from the cooling tower water. Filtration is required to be performed early in the process as the removal of suspended solids can help protect membranes and ion exchange resins from fouling. With proper filtration, suspended particles can be limited down to under one micron.

Ion exchange:

If the hardness level in the makeup or source water is remarkably high, then hardness removal treatment is required, which usually includes using a softening resin with a strong acid cation exchange process, whereby resin is charged with sodium ion to grab molecule and release the sodium molecule into the water. It is necessary to remove these contaminants to prevent scale deposits and rust.

Chemical addition:

If necessary, there are three types of chemicals are used in cooling tower water treatment. The first is Corrosion inhibitors as it neutralizes the acidity in the water and protects metal components. Algaecides and biocide are used to minimize the growth of microbes and biofilms. And the third one is scale inhibitors to prevent contaminates from scaling.

Side-stream filtration:

If the cooling tower water is recirculated throughout the system then side-stream filtration helps remove contaminants that might have entered through a leak or drift contamination. A good quality multimedia filtration unit will filter through 10% of the circulating water.

Blowdown treatment:

Blowdown treatment is effective and also popular where the water is scarce. Depending on the requirement of water circulation to achieve proper cooling, an ion exchange treatment is determined. If the water is required to be discharged then it’s mandatory to follow regulatory requirements.

Summary:

Tower Tech is one of the leading industrial cooling tower manufacturers in India. Along with providing paramount quality of cooling tower water treatment services, we also give an excellent solution for cooling tower installation, maintenance, repair, and refurbishment.