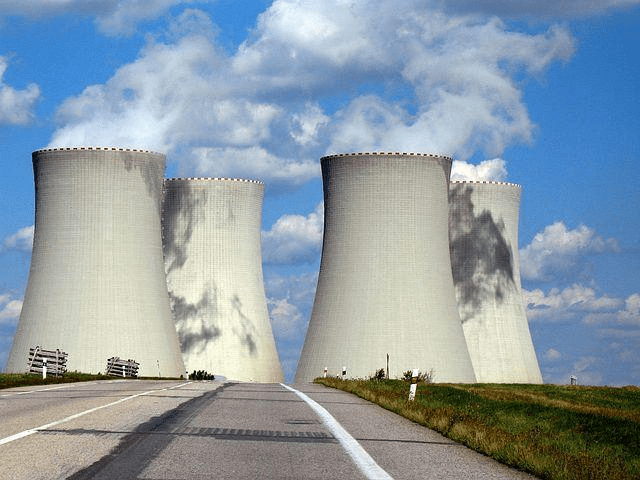

Cooling towers are an essential component in various industrial and HVAC applications. Understanding how they work, their benefits, and maintenance requirements can be crucial for businesses and facility managers alike. To help you better understand cooling towers, we’ve compiled answers to some of the most frequently asked questions. Let’s dive in!

1. What is a Cooling Tower, and How Does It Work?

A cooling tower is a specialized device designed to dissipate excess heat generated in industrial processes or HVAC systems by cooling water. It works on the principle of evaporative cooling, where hot water from the system is circulated through the tower. As it flows through, the water is exposed to air, causing a small portion to evaporate. This evaporation cools the remaining water, which is then returned to the system.

2. What Are the Main Types of Cooling Towers?

Cooling towers come in different types, including natural draft cooling towers, forced draft cooling towers, and induced draft cooling towers. Each type has its specific design and use cases:

- Natural Draft Cooling Towers: These use the natural movement of air for cooling and are ideal for large-scale applications.

- Forced Draft Cooling Towers: Equipped with fans to force air through the tower, these are suitable for smaller systems.

- Induced Draft Cooling Towers: These have fans at the top to draw air up and out, making them efficient for various industrial and commercial applications.

3. What Are Cooling Towers Used For?

Cooling towers are widely used across multiple industries, including power generation, manufacturing, and petrochemicals. They are also an essential part of large HVAC systems for commercial buildings, helping maintain a comfortable indoor climate by removing heat from the cooling system.

4. What is the Difference Between Open and Closed Circuit Cooling Towers?

- Open Circuit Cooling Towers: In open cooling towers, water is directly exposed to the atmosphere, which allows for direct heat exchange through evaporation.

- Closed Circuit Cooling Towers: These towers have a sealed coil that separates the process fluid from the air, making them ideal for systems requiring clean cooling and where water contamination is a concern.

5. What Factors Affect Cooling Tower Efficiency?

Several factors can influence a cooling tower’s efficiency, including:

- Temperature and Humidity: Higher temperatures and humidity levels can impact evaporation rates.

- Water Quality: High mineral content or impurities in water can lead to scaling and reduced efficiency.

- Regular Maintenance: Cleaning, descaling, and inspecting components regularly can help maintain optimal performance.

- Design and Size: Cooling towers should be appropriately sized for the system they support.

6. What Maintenance is Required for Cooling Towers?

Regular maintenance is crucial for maximizing the lifespan and efficiency of a cooling tower. Key maintenance practices include:

- Cleaning: Regular cleaning prevents debris and biological growth, which can obstruct airflow.

- Water Treatment: Ensuring proper water treatment prevents scale buildup and controls bacterial growth.

- Inspection: Conducting periodic inspections helps identify potential issues early.

- Replacing Components: Parts like fans, motors, and fill materials may need replacement over time.

7. How Can I Improve My Cooling Tower’s Performance?

Improving cooling tower performance involves maintaining optimal water flow, ensuring clean fill media, and using energy-efficient components. Routine maintenance, water treatment, and adjustments to airflow can make a significant difference. Adding high-efficiency fans or upgrading old systems to energy-efficient designs can also help.

8. Are Cooling Towers Environmentally Friendly?

Yes, cooling towers are designed to be energy-efficient and reduce environmental impact. By using evaporative cooling instead of mechanical refrigeration, they consume less energy. Additionally, closed-circuit cooling towers conserve water by reducing evaporative losses, making them a greener choice for industries focused on sustainability.

9. What Safety Measures Should Be Taken with Cooling Towers?

Safety in cooling towers is paramount, particularly to prevent issues like legionella bacteria growth. Key safety practices include:

- Water Treatment: Regular chemical treatment to prevent bacterial growth.

- Routine Inspections: Inspecting for leaks, wear, and any signs of microbial contamination.

- Safety Training: Educating staff on maintenance protocols and emergency procedures.

10. How Long Does a Cooling Tower Last?

With proper maintenance, a cooling tower can last 15-20 years or more. Regular inspection and timely repairs of components like fans, motors, and fill material can significantly extend its lifespan. Quality installation and routine water treatment also play a role in longevity.

Cooling towers are an investment in efficient temperature management for your business. Whether you’re new to cooling systems or seeking to improve your existing setup, understanding these essential FAQs can help you make informed decisions about purchasing, maintaining, and upgrading your cooling tower.

For more expert advice or to learn about the latest advancements in cooling technology, Tower Tech India is here to help! Explore our range of cooling tower solutions tailored to meet the demands of diverse industries.