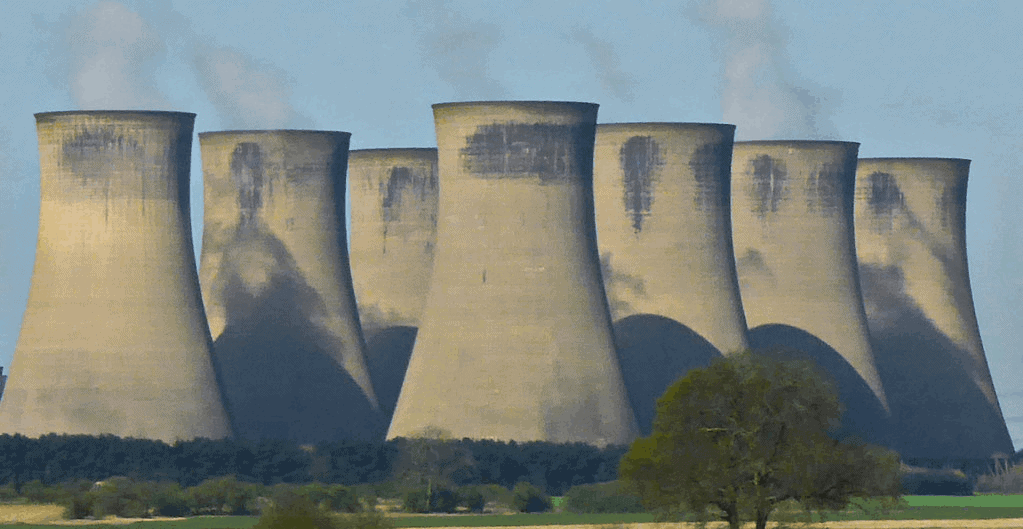

There are major components in cooling towers that make the process of heat exchange possible and efficient. One of those essential components is the cooling tower fill. Let us have a deeper look into understanding cooling tower fill media.

What is Fill in Cooling Towers?

One of the major parts of cooling towers is fill media. It is the main heat transfer area available. Fills are normally made of polypropylene, PVC, or wood.

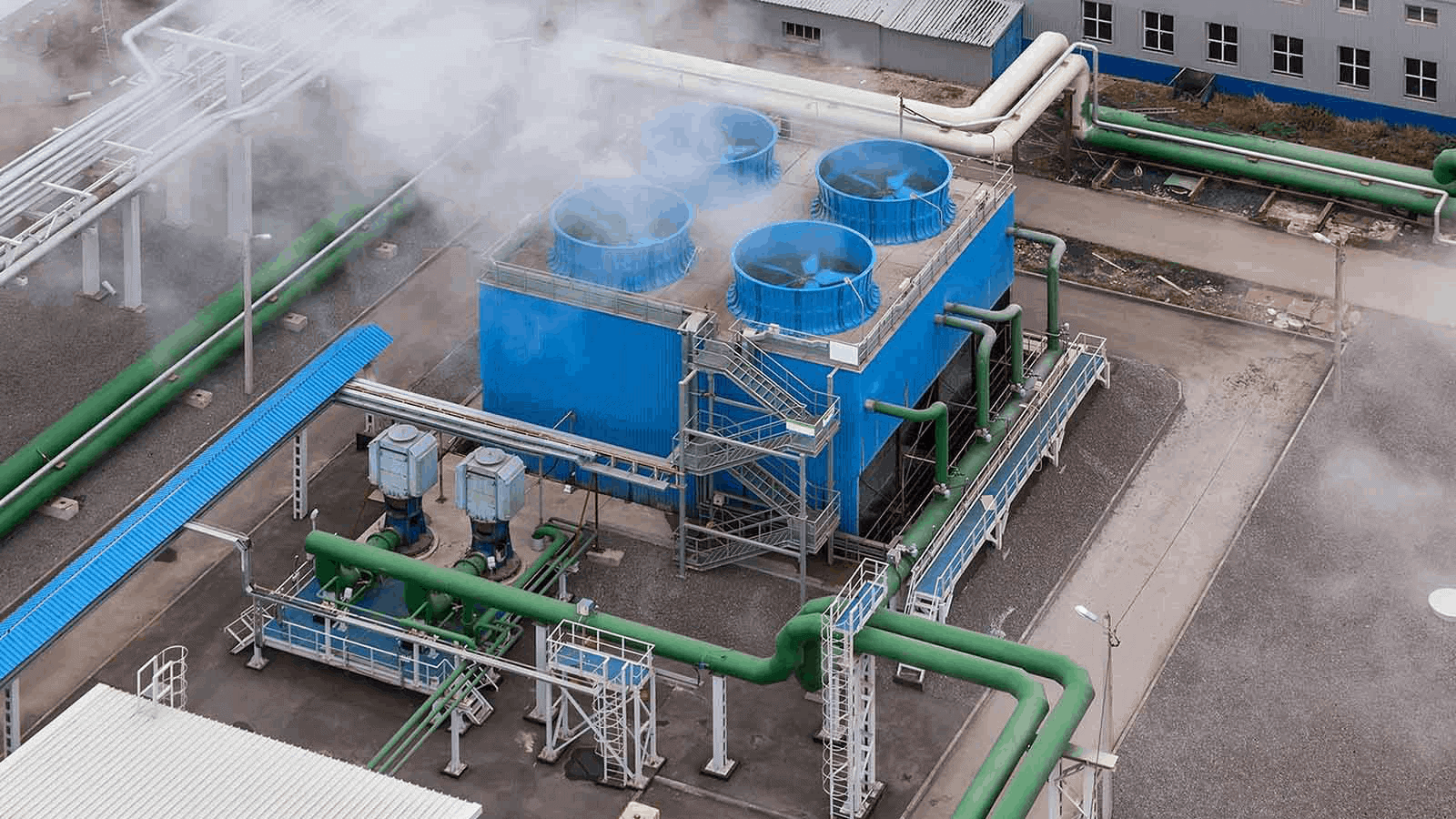

Cooling tower fill is also known as a wet deck or surface, it is a medium to increase the surface area of the industrial cooling towers for the water. The extended surface area enables the optimum level of contact between the air and the water which ultimately allows greater evaporation rates.

Cooling tower fills make it possible to have enough surface area for hot water to cool down quickly.

Types of fills in Cooling Towers

There are two basic types of fill and they are as follows:

Splash Fill

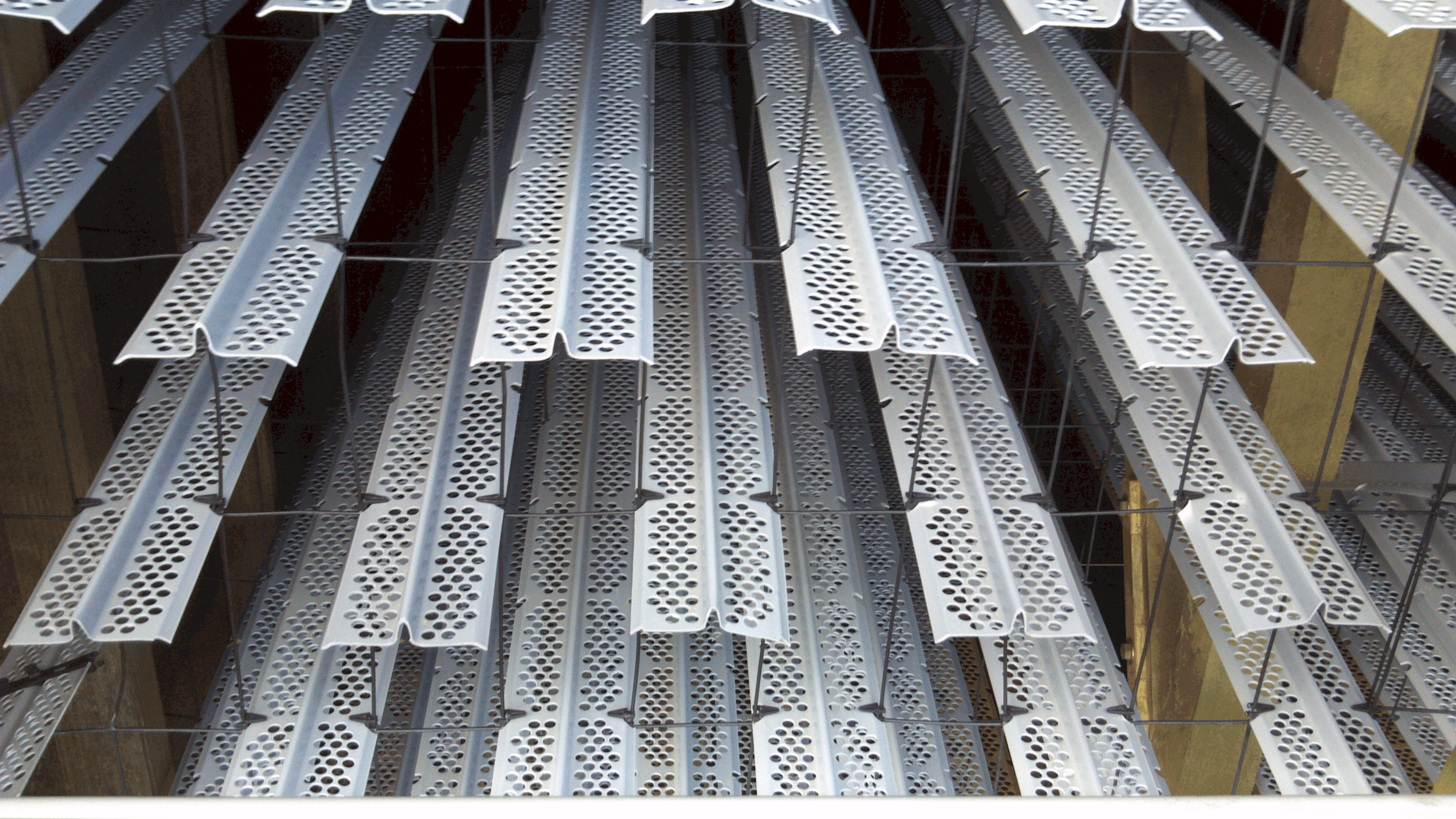

Many layers of slats or bars make a splash fill. When hot water in industrial water cooling towers comes in contact with these bars or slats, it breaks down into tiny particles. These small particles enable increased contact between the water and air that is found within the atmosphere. This process accelerates the rate of evaporation and cooling.

Initially, splash media used to made using wood, however now manufacturers are using more modern designs by adopting PVC. It allows a higher rate of heat transfer. Normally, industries that produce excess filthy water in plenty; use splash fill, since that will convert water into smaller droplets and will separate the dirt and debris from it.

Film Fill

Film fill is made by closely placing thin PVC sheets together. These PVC sheets create a very large surface area in the industrial cooling towers, it allows the circulation of hot air and let the air come in contact with the film of material. It increases the rate of heat transfer which allows the water to cool down. The film fill is specially designed to cool water that is good enough for human consumption; the fill will collect the debris within the water.

Cooling Tower Fill Function

The primary function of cooling tower fill is increasing heat emission, extend the residence time of cooling water, increase heat transfer and heat transfer area, and distribute heat evenly.

The sheet of cooling tower fills is made of a material that is shaped into a grooved pattern, which lets the water travel across. It can be easily stacked into blocks in order to create various heights and thickness to fit individual cooling towers.

Cooling Tower Fill – Principles of Operation

The purpose of the fill application is to cool hot wastewater. The structure of the fill allows hot water to cool quickly, this is the primary reason people choose film fill over splash film in their industrial cooling towers.

The principle of operation in a cooling tower is heat transfer, which happens due to the water evaporation. Evaporation is a natural phenomenon. Water evaporates until it is in contact with air; however, evaporation cannot exceed the saturation point of the air. Consequently, total evaporation will depend upon the moisture-holding capacity of the air, which ultimately depends on humidity.

Purpose of Fill in a Cooling Tower

The purpose of fill in cooling towers is cooling down the water in order to make complete use of water resources. It also focuses on reducing the load of urban tap water supply network and reduction in the operating costs. So cooling water is treated by cooling towers and later recycled as well.

Things to consider while replacing the cooling tower packing:

- It is essential to have diagonally staggered waveforms within the monolithic so that they can have good thermal resistance.

- A blocked plug will make the cleaning difficult and if the jam is serious it will need a replacement as a whole which will ultimately increase the cost.

How to choose a Cooling Tower fill

Film fill and Splash fill both can efficiently facilitate the cooling of water and its evaporation within a cooling tower. However, both types of fills have their own advantages and disadvantages too.

Film fill generates a bigger surface area hence it produces more efficient heat transfer. The drawback of film fill is that, generally, it has a shorter life span due to more wear and tear considering it is constantly exposed to water of high-temperature.

On the other hand, a splash fill fits perfectly if you operate a cooling tower that requires the recirculating of low-quality water with a higher amount of solids in it. The bars and metal grills in splash fill make it much more resilient and highly effective when the cooling tower is exposed to high temperatures.

Cooling towers involve a vital role of manufacturing processes. If you want detailed information about the fill media in cooling towers, it is best to get in touch with industrial cooling tower manufacturers.

Using cooling towers inappropriately in industrial production results in inefficient heat dissipation, stagnant production, and risk of high water temperature.

In Summary

Cooling towers are vital for most manufacturing industries. With the proper knowledge of cooling towers and its components, you can choose the right type of cooling tower fill media for optimal performance and improved efficiency of your equipment.

For cold regions, choose a special filler material based on the local temperature levels. Selecting the filler with high cold resistance could be the right choice.