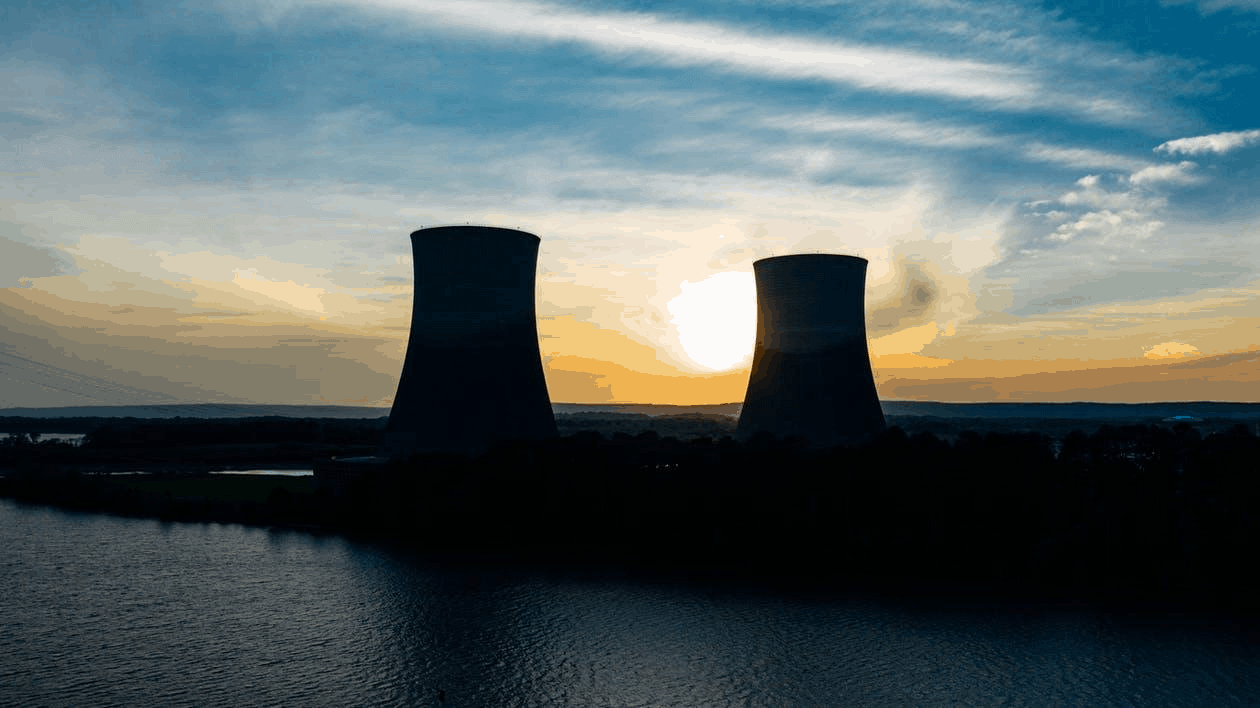

A cooling tower is often used in industrial production to limit the amount of heat that exits the facility and improve the efficiency of the manufacturing process. Cooling towers, which may be small or large, are required to reduce the hot water temperature utilized in industrial operations.

Cooling towers are structures that transfer heat from a building to the surrounding environment and return cooler water to a storage tank. Water is cooled in a cooling tower using industrial pipes that convey the hot water to the tower. Unlike the air surrounding it, this water is heated to a temperature above the dew point. It becomes hotter when it passes through the chiller’s cooling coil, thus the name.

In terms of industrialization and manufacturing processes, India is rapidly expanding. Since more factories are being developed every day, more cooling towers will be required in the manufacturing line. Because of India’s rapid industrialization and manufacturing practices, this is directly affected. Towertech, the world’s leading cooling tower manufacturer, is the finest option.

What is a Cooling Tower?

The cooling tower extracts heat generated as a byproduct of the industrial process. Heat is transferred from the object to the surrounding air via water. A very little amount of water is often evacuated from cooling towers before the device passes through and absorbs it.

A cooling tower uses a unique heat exchanger that covers the gap between air and water to chill water. When water is placed into the tower, a little portion of it evaporates, lowering the temperature.

The cooling tower’s fundamental component is water, which is responsible for transporting heat from one point to another. Cooling towers are necessary for industries such as additive manufacturing, tool and die-cutting, chemical production, lasers, milling machines, and semiconductors to keep items and equipment cool.

How does the Cooling Tower Work?

A cooling tower must be able to transmit heat to work correctly. According to thermodynamics, heat may travel from hot to cold water, which is how this is performed. Throughout the production process, the region creates a lot of heat. Before it can be used again in production, the hot water must be cooled.

Local enterprises supply hot water for the cooling tower. Pipes transport hot water to the very top of the tower. When the tower reaches its maximum height, hot water is fed into it through nozzles.

When water comes into contact with air, it cools. The leftover cold water is then dumped into a basin buried. It is transferred to an industrial site to be reused in the production process.

Small water droplets are blasted over the cooling tower as it fills with hot water from the reservoir. By expanding the surface area of the water, the quantity of heat that may be carried by evaporation is increased.

Types of Cooling Towers:

Cooling towers are modified to satisfy the demands of the many industries that employ them. Towertech is happy to provide a diverse assortment of cooling towers to achieve the greatest possible air circulation and temperature management. Here are some examples of cooling towers and what they are used for.

Crossflow Cooling Tower

In a cross-flow heating system, air and hot water flow opposite. It has an FRP transmission basin and a target nozzle at the tower’s very top.

In honeycomb fills, channels are left open so that water can flow vertically down the walls of the channels. This lets gravity spread the water evenly throughout the fill medium.

When the fan and motor are directly linked, air can be pulled over the fill medium. The fan should be on its side. A small amount of water can be evaporated to get rid of the extra heat made by the extra water. The fan and motor are placed on the side, and the air is then let out of the ship through the vented deck.

Water from the cooling tower that has already been used is collected in the cooling tower collecting basin and reused by several businesses.

Modular Cooling Towers

There must be at least one cooling tower module in a modular cooling tower for the whole thing to stay stable even when all the legs are out. This style is also known as a modular cooling tower. A modular cooling tower is this kind of cooling tower.

When an assembly needs more than one cooling tower module, the modules’ frames next to each other are linked together.

At the bottom of the panels is a reservoir or airflow chamber. This is where the airflow forces meet. The airflow goes up and down because of the fill sheets, the exit plenum chamber, and the fan cowl. It has a motorized fan in the chamber where the air comes out of the device.

Round Shape Cooling Towers

You may not have heard of it before, but the cooling tower that looks like a bottle is a rather familiar sight. When the water in a cooling tower is heated to between 50 and 4 degrees Celsius, the water is cooled.

This is accomplished by directly using induced draught with the fan, directly linked to the motor. As a result, more heat is removed from the environment. If air is sucked into the intake region and forced through the fill media, it is feasible that heat energy created by water moving through the fill media might be removed from the system.

As a result of part of the water evaporating, the remaining heat in the water is no longer present.

Visit this website to get further information on the ecologically friendly technology and products offered by the cooling tower manufacturer, Towertech.