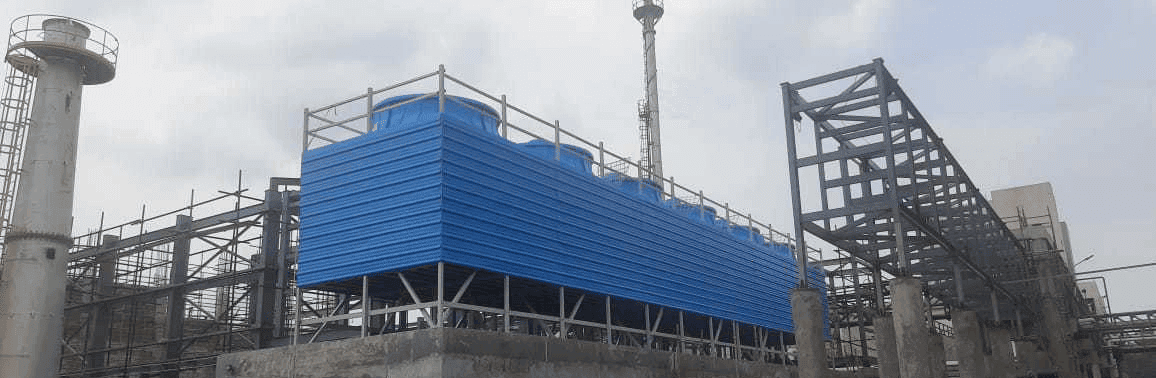

EVAPORATIVE COOLING TOWER

Cooling towers are being widely used in the industries for the removal of unwanted heat from one’s factories. After removal of the unwanted heat, the machines work more efficiently because of the good working environment.

Cooling is provided via evaporative cooling towers based on a planned dew point temperature. Evaporative cooling towers generally chill water to around 85° F, although they may cool to as low as 65° F. They are the most cost-effective method of cooling huge volumes of water.

The method of eliminating hot air from a medium by evaporating water is known as evaporative cooling.

Latent heat is required to raise the temperature that water stores. The surface temperature drops as heat transfers from the surface to the water.

Working condition of the Evaporative Cooling Tower

The transmission and evaporation of temperature differences are important in the cooling system's operation. To eliminate the latent heat of vaporization, the air and water are combined at different temperatures, resulting in a reducing and cooling impact on the heated water.

To obtain the cooling effect, a part of the water is converted to the vapor state, and the hot gas of evaporation is discharged into the environment.

Hot water from a production plant is pushed to the top of the chamber of the cooling tower, where the water distribution system is located for evaporative cooling. The water is subsequently delivered to the moist deck through cooling tower outlets. The heat in the water is eliminated through evaporation.

Cooling Tower classification

There are many types of cooling towers available, but choosing the right one is difficult. Cooling towers from Towertech are the best ones available in the market. According to types, draft cooling towers can be classified into:

- Natural Draft cooling tower

- Mechanical Draft cooling tower

Natural Draft Cooling Tower

The Natural Draft Cooling Tower is a direct-contact device that is open to the air. It uses a radiator to allow hot water from the plant to be cooled by coming into direct contact with natural air. At the top of the tower, heated air rises, while cold water accumulates at the bottom.

This technique has a simple construction, but it has a significant initial investment because of the considerable height required to produce the draft.

Mechanical Draft

In a mechanical draft type cooling structure, the air supply can be adjusted by

using a fan and supplying the air in different types of directions so that the hot

water gets cooled easily.

Easy installation, cheap capital expenditure, low pumping head, tight control over

water temperature are the characteristics of the mechanical draft cooling tower.

The different direction of air and water supply is given below:

- Counterflow: Where the water and air supply are in a different direction.

- Parallel flow: Here the water and air flow are in the same direction.

- Crossflow: The water drips across the air chamber in an induced draught

tower, the fan creates parallel airflow.

Evaporative cooling towers by Towertech are worth giving a shot when you are planning to set up cooling towers in your industry. Get the best ones from Towertech!